In the Pakistan market, prices for the same Epson L1800 can vary widely.Some offers look very cheap, others are clearly more expensive — yet almost all sellers claim their machine is “suitable for DTF business.”

For entrepreneurs planning to open a print shop, start T-shirt customization, or run a small personalized printing business, the real concern is not technical specifications.

The real questions are: Is this investment reasonable? Can it pay back? Will hidden costs keep increasing later?

This article focuses on real price ranges, common reasons behind price differences, machine stability, and long-term consumable costs, helping you judge whether the Epson L1800 DTF price you’re seeing is truly worth it.

How Much Does an Epson L1800 Cost in Pakistan?

In Pakistan, the price difference for the Epson L1800 is not random.

It usually depends on several practical factors, such as whether the machine is brand new or refurbished, whether it comes from an official channel, and whether basic warranty or after-sales support is included.

Based on current market conditions, the typical price for the original Epson L1800 printer (machine only) ranges from PKR 100,000 to 300,000.

Lower prices are often linked to refurbished or old-stock machines, while higher prices usually emphasize condition, sourcing, or service support.

It’s important to clarify one common misunderstanding: this price only covers the printer itself.

Many first-time buyers assume that owning an L1800 means they can immediately start a DTF business. In reality, there is a clear gap between “buying the printer” and “running DTF production.” The additional system setup and consumables are often underestimated and later become a major source of confusion and extra cost.

Original L1800 vs. DTF-Modified Version: Which Is Better for Business?

This is where many beginners make costly mistakes.

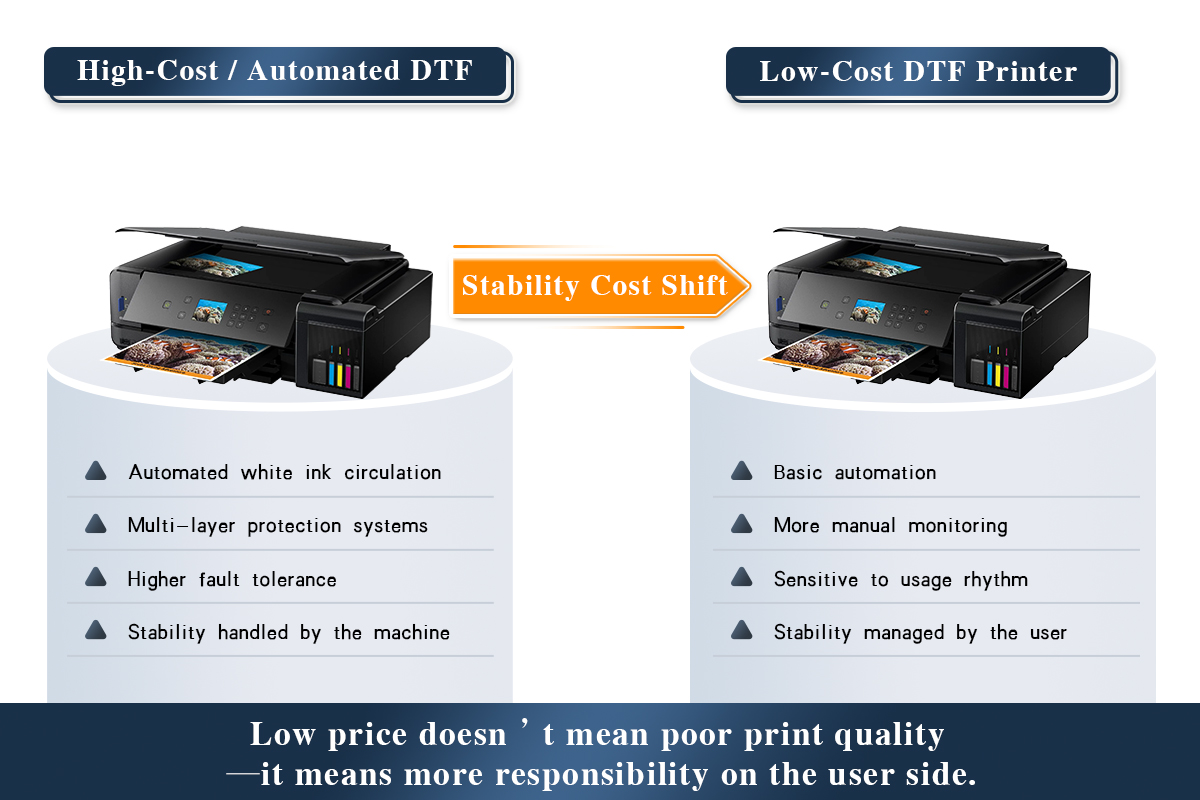

Once you understand the basic L1800 price range, the next real decision is whether to buy a standard original L1800 or a DTF-optimized / modified version.

Original Epson L1800 (PKR 100,000–300,000)

Best for users with limited budget, technical understanding, and willingness to experiment.

Risk: without proper maintenance and tuning, downtime and material waste can significantly delay payback.

DTF-modified / optimized L1800 (higher upfront cost)

Best for users who want to enter the market quickly, reduce trial-and-error, and focus on stable order delivery.

Risk: higher initial investment, but often lower long-term operational cost.

In practice, DTF-optimized L1800 machines usually cost more because the configuration is clearer. White-ink circulation, basic settings, and workflow have already been adjusted, making it easier to start production quickly. For small studios, this often means fewer early-stage problems and less wasted time.

Buy Locally or Import?

This is a very practical dilemma for Pakistani users — sometimes even more confusing than price itself.

Local purchase advantages are obvious: fast delivery, easier communication, and sometimes local after-sales support. This appeals to users eager to start quickly.

However, local purchases also come with risks.

Based on Winnerjet’s experience working with Pakistan customers, some buyers later discovered refurbished machines sold as new, inconsistent modification quality, or unclear pricing details. The machine may seem reasonably priced at first, but hidden costs appear during actual use.

Imported solutions, on the other hand, usually offer better clarity: configuration, pricing, and usage logic are more transparent, and the overall DTF workflow is more complete. When combined with structured remote technical support, long-term stability can actually be easier to control.

Of course, importing also requires consideration of shipping, duties, remote support availability, and stable consumable supply.

The key issue is not local vs. import — it’s whether you clearly understand what configuration you are actually buying.

Are Consumables Expensive? Can You Keep the Profit?

From Winnerjet’s long-term experience supporting DTF customers, profitability is determined less by the price of a single consumable and more by the combination of consumables and machine stability.

In real DTF production, the main consumables include white ink, PET film, hot-melt powder, and cleaning solution. Among them, white ink has the highest consumption and the biggest impact on stability and cost control.If white ink flow is unstable or sedimentation control is poor, frequent head cleaning becomes unavoidable, directly affecting order delivery. In practice, many profits are not lost to “expensive consumables,” but to downtime, waste, and rework.

Winnerjet specializes in DTF inks and consumables, and one consistent pattern we observe is this:Ink–head mismatch increases cleaning frequency; poor film–powder compatibility leads to repeated test prints; excessive cleaning to prevent clogging actually raises ink and solution consumption.

That’s why Winnerjet focuses on stability, batch consistency, and matching, not simply lowering unit price. When ink parameters are stable and consumables work well together, test prints and rejection rates drop significantly, making real per-print costs predictable.Long-term profitability depends on using a repeatable, stable consumable system, not constantly switching to cheaper materials that require new rounds of trial and error.

Can You Recover the Investment?

For small businesses focused on T-shirts, apparel, gifts, and advertising prints, the core concern is simple: how fast can the investment be recovered?

In reality, payback depends on three factors:

- Order stability – consistent orders dramatically improve machine utilization.

- Machine reliability – downtime affects delivery and customer trust.

- Consumable waste control – white ink loss, test prints, and rejected films quietly eat profit.

Based on real cases Winnerjet has seen, when orders are stable, machines are properly maintained, and consumables are well controlled, many small studios recover their investment within 3–6 months.

The key is not buying the cheapest machine, but ensuring stable operation and predictable costs.

Final: How to Tell If You’re Paying Too Much

When evaluating an Epson L1800 DTF price in Pakistan, the real question is not the number — it’s what that price actually includes.

If a quote cannot clearly explain whether the machine is new or refurbished, how it’s configured for DTF, or what support is available when problems arise, then even a low price may turn out to be expensive in the long run.

From Winnerjet’s experience, many users later realize they didn’t overpay — they simply made decisions without fully understanding configuration and long-term cost structure. When machines run stably and consumables match well, costs become predictable and payback becomes clearer.

📌 A simple rule: If, before placing an order, you can clearly explain the machine configuration, usage workflow, and ongoing consumable costs, then the price you’re paying is usually reasonable.