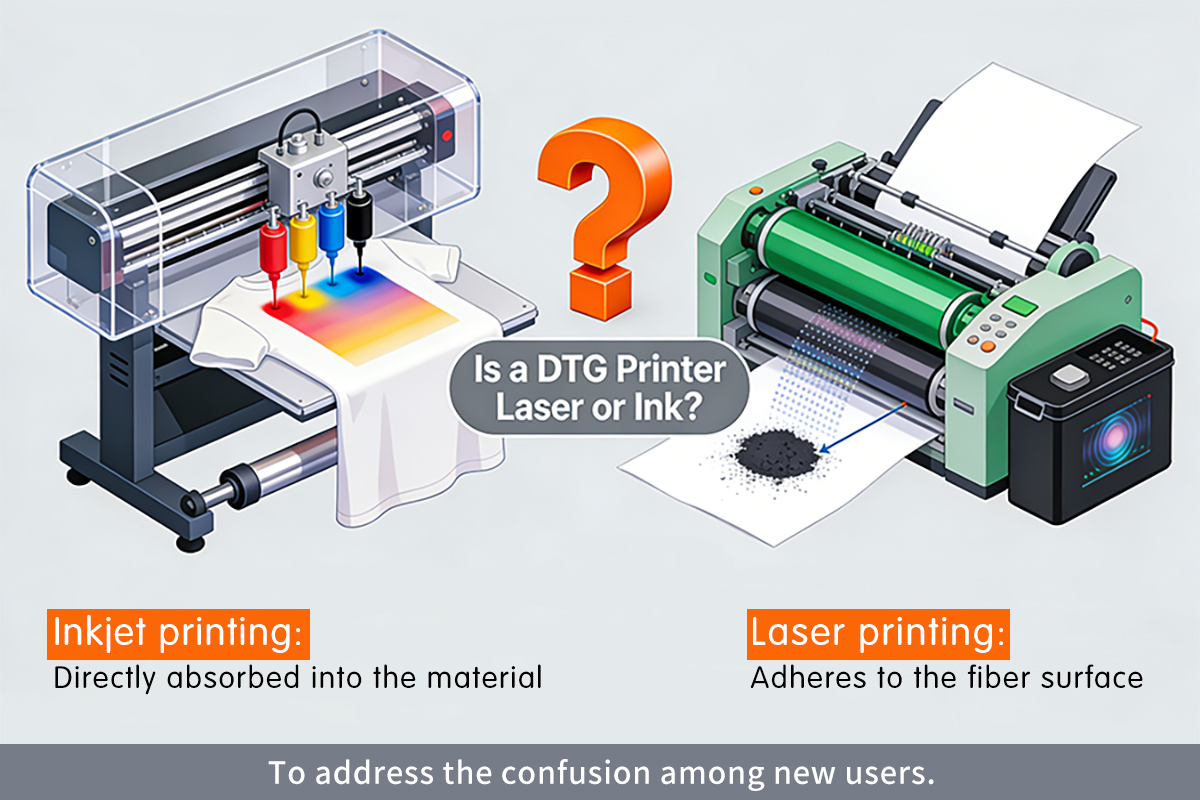

If you’re just starting your custom T-shirt business, the technical jargon can be overwhelming. One of the most common questions newcomers ask is: “Is a DTG printer laser or inkjet?”

The short answer: DTG is 100% Inkjet technology.

While the heat-pressing stage might remind you of the dry heat used in laser printing, the way the image is applied to the fabric is fundamentally different. Let’s break down the core differences in two minutes so you can make the right investment for your business.

The Core Tech: Inkjet vs Toner

While both methods produce images on garments, their underlying physics and consumable requirements are worlds apart.

DTG (Inkjet): Digital Direct Injection

A DTG printer works like a high-end industrial version of the inkjet printer on your desk. It utilizes precision Piezoelectric Printheads to spray hundreds of millions of microscopic Water-based Pigment Ink droplets directly into the fabric fibers.

Winnerjet Insight: The secret to this technology is “particle size control.” As a professional supplier, we ensure our ink particles are evenly distributed at the nano-scale. This doesn’t just deliver Professional Results with fine detail—it’s critical for preventing clogs and keeping your production line running.

Laser (White Toner): Physical Thermal Transfer

In contrast, Laser Transfer technology uses dry plastic powder (Toner). The image is first “drawn” onto a drum via electrostatic attraction, transferred to a special film, and then “melted” onto the garment surface using high temperature and pressure.

The Process Gap: Laser transfer is essentially “applying a film” to the shirt, whereas DTG “dyes” the fabric itself.

The Comfort & Breathability Test

This is the most noticeable difference for the end-user and a deciding factor for high-end custom markets.

DTG Ink (The Penetration Experience): Because the ink is water-based and consists of nano-particles, it penetrates and embeds (Soaks into) the cotton fibers. This allows the print to become one with the fabric, maintaining the natural micro-pores of the garment.

The Result: An incredibly soft, No-feel hand that remains highly breathable. It won’t give your customers that “sweaty chest” feeling during the summer.

Laser Toner (The Overlay Experience): Laser toner is essentially plastic. During heat pressing, these particles melt into a continuous film that sits on the surface (Layer on top). It’s like sticking a thin sheet of plastic onto the shirt.

The Result: A noticeable Plasticky feel that is stiff and non-breathable, as it seals off the fabric’s natural airflow.

Quick Comparison: DTG vs Laser

| Feature | DTG (Inkjet Technology) | Laser (White Toner) |

|---|---|---|

| Hand-Feel | Soft & Breathable (No-feel) | Plasticky (Thick/Heavy) |

| Cost Per Print | Low (Ideal for volume) | High (Expensive paper) |

| Washability | High (Embedded in fibers) | Medium (Prone to cracking) |

| Best Fabric | 100% Cotton | Blends / Polyester |

Profitability Analysis: Which Tech Actually Saves Money?

Newbies often focus only on the machine’s price tag, but seasoned pros look at the Total Cost of Ownership (TCO). Your choice of technology defines your profit margins.

Laser: Low Entry Barrier, High Running Costs

Laser printers are often cheaper upfront, making them attractive for startups. However, due to the high cost of Transfer Paper and toner cartridges, the cost-per-garment is high and stays high. This is best for ultra-small runs (1–5 pieces) where customers don’t mind a premium price.

DTG: Higher Investment, Higher Long-term Margins

While the initial investment for a DTG setup is higher, the cost-per-print using Water-based Pigment Ink is extremely low.

Winnerjet Expert View: Many owners complain about DTG maintenance costs, but that is usually due to unstable, low-quality inks causing frequent auto-cleanings. By using high-stability Winnerjet DTG Ink, you can reduce non-productive ink waste by approximately 30%.

The Bottom Line: Higher volume leads to a much faster and higher ROI (Return on Investment).

Why Ink Quality Makes or Breaks Your Business

In the DTG industry, ink is your lifeblood. Under a microscope, the gap between premium ink and budget consumables is massive.

Nano-scale Pigments: Color Meets Longevity

High-quality DTG Ink particles are strictly controlled under 0.2 micrometers. This allow the particles to “dye” the fibers rather than “sticking” on top like toner.

Technical Insight: Ultra-fine particles are the only way to achieve true Clog-resistance. Low-grade inks have coarse particles that clump together like “sand” in the delicate veins of your printhead, leading to permanent Printhead clogging.

Chemical Stability & Washfastness

Beyond size, the chemical formula determines the life of the print. Cheap, unstable inks lead to:

Washfastness Failure: Binders fail to cross-link during curing, causing the print to fade or crack after one wash. This destroys your brand reputation and causes customer churn.

Batch Variance: Poor ink separates in the bottle within weeks, leading to inconsistent colors that fail the standards of professional B2B clients.

The Winnerjet Standard: Our inks undergo multi-stage micron-level filtration. We ensure your printer can “start on the first click” even after sitting idle, and your prints remain vibrant after 50+ washes.

The Verdict: Which Choice Delivers Professional Results?

The conclusion is clear. While both technologies have their place, DTG remains the gold standard for retail-quality apparel.

If you are chasing vibrant colors, breathtaking detail, and the kind of Professional Results that keep customers coming back, the inkjet-based DTG solution is the only way to go.

Thinking Beyond the Machine: Stability is Everything

As a veteran industry supplier, we must remind you: owning an expensive printer is only the beginning. A perfect final product is 70% dependent on the stability and quality of your ink. Even the best equipment will fail in a cycle of endless repairs if fed impure, sediment-heavy consumables.

At Winnerjet, we provide high-standard DTG Ink for operators who refuse to settle. Our solutions aren’t just about a moment of bright color; they are about the Stability of your production line and ensuring every garment that leaves your shop feels like a premium global brand.

Want to unlock the secrets of DTG consumables?

Now that you know the logic behind the tech, the next step is learning how to choose ink that prevents Printhead clogging and ensures your prints survive the laundry.

👉 Read our Deep-Dive Guide:What Kind of Ink Do DTG Printers Use: Choosing the Right Ink for Professional Results