When you are searching for a low price DTF printer, it usually means you already understand what DTF is and have looked at different price ranges. What makes you hesitate is no longer whether the machine can print, but how to avoid choosing the wrong equipment under a limited budget.

Low price itself is not the problem. The real risk lies in which costs have been removed, and whether those costs will later be transferred to your time, maintenance effort, and delivery stability.

In the DTF industry, low-price solutions are often not “unusable,” but they place higher demands on printing rhythm, operating discipline, and risk control. If these realities are not clearly understood before purchasing, the budget you think you saved may be continuously consumed later. This article looks at low-price DTF printers from a real usage perspective, helping you distinguish which low-cost options are controllable and which are more likely to create hidden costs during actual operation.

I. Comparison of Five Common Low-Price DTF Printer Options

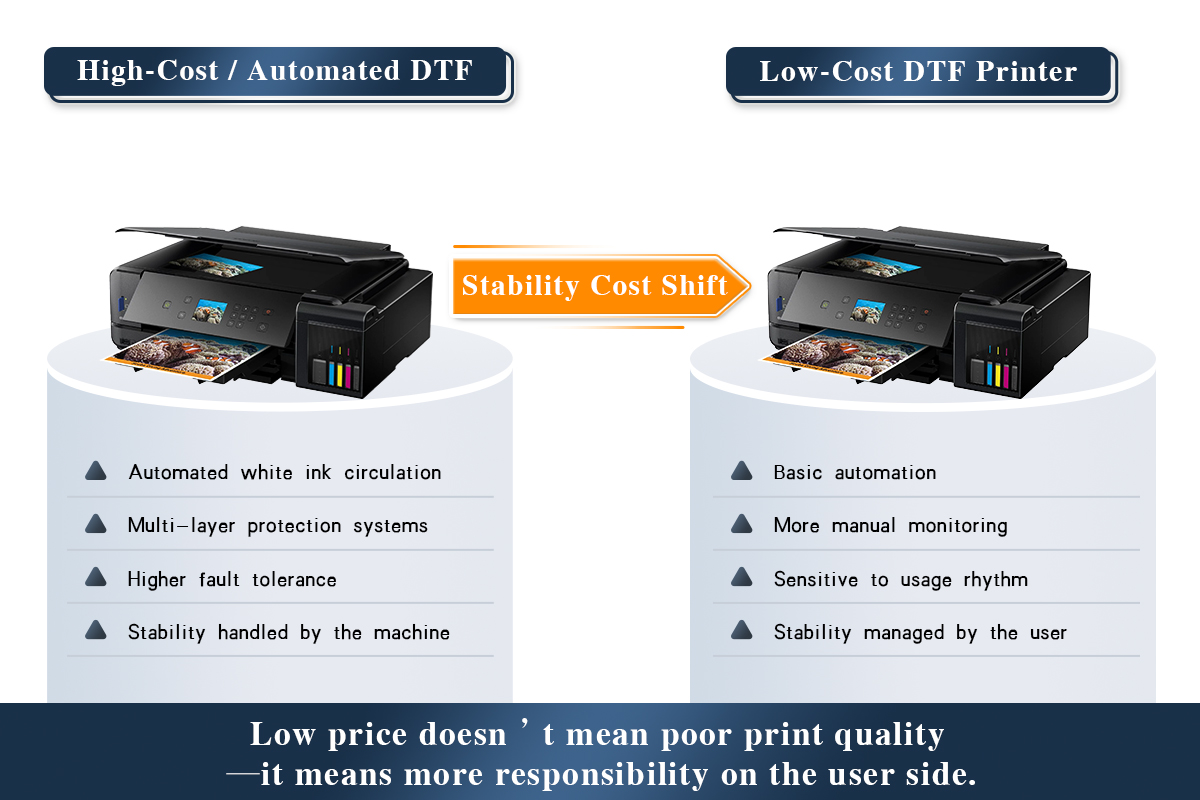

In the DTF industry, low price does not mean poor print quality. Instead, part of the “stability cost” that would normally be handled by the machine is shifted to the user. What you buy is not a machine that cannot be used, but a cost-effective device that requires better understanding and more attention.

Understanding these differences matters far more than simply comparing prices.

1. Epson L1800 DTF Printer: Low-Cost Entry Level

The Epson L1800 is a typical converted DTF entry solution. It has a low equipment cost, good print precision, and a relatively simple structure.

Advantages: Low investment, good image quality, suitable for small-scale printing with a stable rhythm.

Limitations: Limited automation, sensitive to white-ink maintenance and usage frequency, not suitable for long downtime or irregular use.

If optimization is done at the factory stage specifically for DTF—such as ink path design and baseline parameter tuning—rather than relying entirely on users to adjust later, entry-level machines based on the L1800 architecture can actually be easier to control during the early stage.

Taking the L1800 entry configurations delivered by Winnerjet as an example, the focus is not on adding more features, but on optimizing white-ink circulation logic, ink path structure, and factory calibration processes. This helps reduce unpredictable issues that beginners most often encounter, making it more suitable for users who want to control their budget without relying purely on trial and error.

2. Brother GTX Pro: Stable Output Type

The Brother GTX Pro is closer to a desktop device designed for continuous production, with more mature performance in speed, workflow, and stability.

Advantages: High output efficiency, clear operation logic, relatively controllable failure rate.

Limitations: Higher initial investment than entry-level models, still requires standardized daily maintenance.

From a professional supplier’s perspective, this type of equipment is more suitable for users who have already entered a stable order-taking stage and want to reduce manual intervention, rather than those simply pursuing the lowest startup cost.

3. Canon Image PROGRAF PRO-1000: High-Quality Output Focus

The core strength of the PRO-1000 lies in color accuracy and detail rather than production capacity, making it more suitable for high-quality output scenarios.

Advantages: Accurate color reproduction, fine image detail, good stability.

Limitations: Limited printing speed and continuous production capability, not suitable for scaled orders.

In real use, this type of device is more often positioned as a supplementary solution rather than a primary DTF production machine.

4. UV DTF Printer Pro-X: Multi-Application Expansion Type

The UV DTF Printer Pro-X emphasizes application versatility and can be used for labels, decorative stickers, and other products.

Advantages: Broad application range, one machine supports multiple product types.

Limitations: Higher technical complexity, greater requirements for material selection and operational standards.

Based on delivery experience, this type of equipment is more suitable for users with clearly defined application scenarios, rather than those simply “trying out” DTF.

You can learn more about UV DTF printers here:

https://www.winnerjet.com/top-5-uv-dtf-printer-for-startups/

5. A3 XP600 DTF Printer: Ultra-Low-Cost, Controllable Option

A3 XP600 is one of the most common low-budget standard DTF configurations, emphasizing minimal entry cost.

Advantages: Clear price advantage, compact structure, easy to start.

Limitations: Higher maintenance frequency, sensitive to environment and operation discipline, not suitable for high-intensity continuous operation.

At the XP600 price level, what truly differentiates user experience is often not the printhead itself, but the stability of the white-ink system, overall machine structure, and factory testing standards.

In the A3/A4 XP600 DTF models delivered by Winnerjet, the priority is not pushing the price even lower, but converting common “random issues” at this price point into predictable and manageable maintenance tasks. This is why XP600 does not automatically mean high risk, but rather a low-cost solution that trades operational management for startup savings.

II. What Does a Low-Price DTF Printer Actually Cut? The Real Threshold Beyond Price

Many regrets about low-price DTF printers do not come from machines being unusable, but from failing to understand before purchase where the cost savings actually come from—and whether those reductions exceed one’s own tolerance.

In practice, low-price DTF printers usually reduce costs in the following key areas.

First, fewer automation and protection mechanisms.

Low-price solutions often retain only basic functions. White-ink circulation, standby protection, and error alerts may be incomplete or require manual intervention. This means the machine rarely detects issues in advance, relying more on the user’s observation and judgment.

Second, smaller fault tolerance.

With simplified systems, the machine becomes more sensitive to operating standards and environmental conditions. Temperature and humidity fluctuations or improper operation are more easily amplified into stability issues. These systems are not uncontrollable, but they are less forgiving.

Third, high sensitivity to usage rhythm.

Low-price DTF printers are generally not suitable for long downtime or irregular use. Frequent starts and stops increase white-ink maintenance pressure, requiring more time and attention from the user.

It is important to emphasize that what is “cut” does not automatically equal unacceptable flaws. The key is not the price itself, but whether you are at a stage where you can accept more manual involvement and have the time and energy to manage these trade-offs.

For this reason, instead of repeatedly asking “What is the minimum cost to start DTF,” it is more practical to first confirm a few realistic conditions.

Do you have a relatively fixed printing rhythm?

Low-price solutions work better with stable, continuous use. Irregular use often causes more issues.

Can you accept maintenance as part of daily work?

If you expect the machine to run with minimal attention, low price may not mean convenience—it may mean ongoing time consumption.

How much does one day of downtime affect your business?

If delivery schedules are tight and tolerance is low, uncertainties in low-price solutions are quickly magnified into risk costs.

Ultimately, the true bottom line is never a specific price number, but whether—when problems arise—you have the ability and margin to keep them within an acceptable range. Only under this condition can low-price DTF become a rational starting point rather than the beginning of regret.

III. Is Low Price a “Controllable Hassle” or an “Uncontrollable Risk”?

This is the key distinction between smart cost saving and later regret. Low price itself is not the issue—the result depends on whether the problems remain within your control.

Controllable hassles usually share clear characteristics:

issues show warning signs rather than appearing suddenly; maintenance procedures are clear; and through experience, repeated problems can be avoided. These consume time and attention but do not spiral out of control.

Uncontrollable risks, by contrast, appear randomly. Small issues escalate quickly, downtime becomes unpredictable, and delivery and cash flow are directly affected. At this point, the machine stops being a tool and becomes a constant source of pressure.

It is important to note that a low price DTF printer does not automatically equal uncontrollable risk. However, it requires the user to actively participate in risk management rather than relying entirely on the machine to absorb all uncertainty.

If you expect the equipment to handle all stability costs on its own, low-price solutions are often unsuitable. But if you clearly understand which issues are predictable and manageable, low price can be a rational, controllable choice.

From Winnerjet’s after-sales experience, the outcome of using low-price DTF printers largely depends on whether users clearly understand what they are trading price for. When expectations are aligned and usage rhythm is stable, low-price solutions are often easier to control. When expectations and reality diverge, problems rarely originate from the equipment itself.

IV. Why Do Some Users Actually Run Low-Price DTF More Smoothly?

In real use, we observe a counterintuitive but often overlooked phenomenon: low-price DTF printers are not unfriendly to all beginners. In certain users’ hands, they actually run more smoothly.

The first group includes users with inkjet, photo printing, or related experience.

They are familiar with printhead behavior, ink systems, humidity control, and daily cleaning. For them, low-price DTF is not an incomprehensible machine, but a relatively simple system that requires attention. Experience compensates for part of the stability cost.

The second group is studio-type users rather than purely order-driven operators.

Studio users often have more flexible production rhythms, allowing for testing, adjustment, and short downtime. They focus on workflow and cost control rather than maximizing output every hour. In this environment, low-price DTF printers are more manageable and risks easier to absorb.

The third group includes users who can make basic judgments without fully relying on after-sales support.

This does not mean no support is needed, but that users can assess issues and priorities when problems arise. Low-price equipment relies more on user participation. When every issue is expected to be “automatically solved,” pressure increases; when users intervene early, many problems stop at the initial stage.

Overall, low-price DTF printers are not inherently difficult to use. They are better suited for users who understand equipment logic, participate in management, and are willing to trade experience for cost. In other words, low-price solutions favor those who understand machines, not those who fully rely on them.

V. Are You at the Right Stage to Start with a Low-Price DTF Printer?

Based on Winnerjet’s practical contact and after-sales experience, whether a low-price DTF printer is suitable depends less on price itself and more on whether your current stage matches its usage requirements.

Low-price DTF printers are often a reasonable choice if:

you are new to DTF but already have experience with inkjet printing, heat transfer, or related equipment;

your budget is limited but you have sufficient time and energy to learn and adjust;

you can accept an initial learning cost instead of immediately pursuing high commercial stability.

At this stage, low-price equipment functions more as a transitional tool and learning platform rather than a long-term, high-load production machine.

Low-price solutions are less suitable when:

DTF is already your main or sole income source with high stability requirements;

you have little time for daily maintenance and expect automation;

or you prefer a one-time investment with minimal involvement for years.

In our view, low-price DTF is better seen as a validation tool—used to verify demand, workflow, and rhythm—rather than a machine meant to carry a fully matured business model long term.

Final Thoughts: With Low-Price Solutions, “How You Use It” Matters Most

Not everyone has the budget to start at the top. With low-price DTF machines, correct usage matters more than price itself. Based on Winnerjet’s after-sales experience, stable operation usually requires maintaining a fixed printing frequency (even test prints), controlling temperature and humidity, performing basic manual checks, and keeping simple usage and maintenance records.

Ultimately, whether a low-price DTF printer works well depends on whether you clearly understand what you are trading price for and prepare accordingly. As a DTF equipment supplier serving users at different stages, Winnerjet prefers to help you determine suitability before purchase rather than paying for mismatch afterward. If you are unsure whether your usage rhythm, maintenance capacity, or business needs fit a low-price DTF printer, evaluating real scenarios against specific configurations is often more valuable than comparing prices alone.