DTF printing, short for Direct-to-Film printing, is a way to transfer designs onto fabrics using a film. Unlike traditional methods that print directly on garments, DTF prints your image on a special film first, adds adhesive powder, and then heat-presses it onto fabric. This makes it great for bright, detailed, and long-lasting prints.

🖨️ How Does DTF Printing Work?

Here’s how DTF printing works in five simple steps:

- Design Your Artwork: Use graphic software (like Photoshop) to prepare your design with a transparent background.

- Print on DTF Film: The design is printed onto a PET film using DTF inks. First, the color layer is printed, followed by a layer of white ink.

- Apply Adhesive Powder: While the print is still wet, you apply a special powder adhesive evenly to the back.

- Melt the Powder: Heat the film slightly to melt the powder and make it ready for pressing.

- Heat Press onto Fabric: Place the film on your garment and press it with heat (usually 160–170°C for 15 seconds). Then, peel the film—done!

🌟 What Are the Main Benefits of DTF Printing?

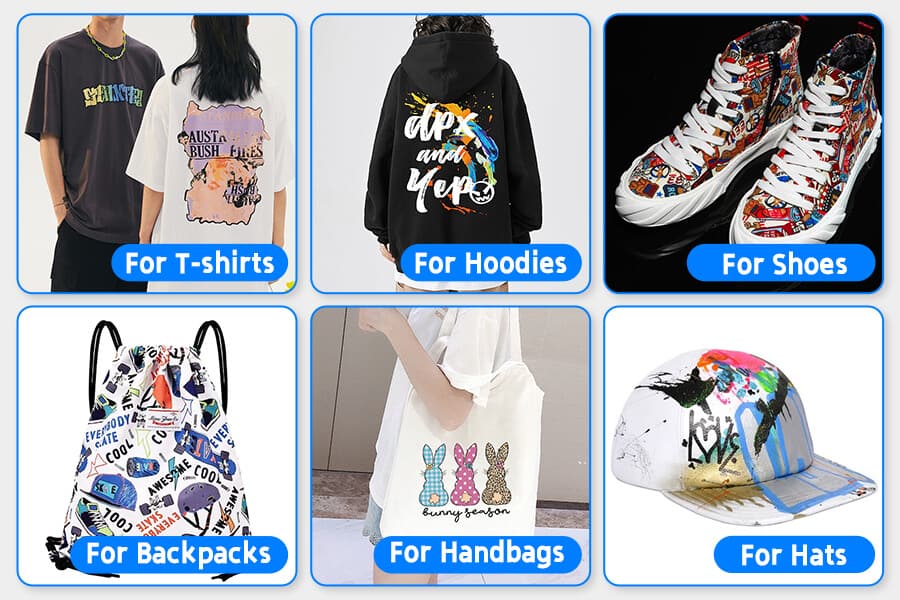

- Works on many fabrics: cotton, polyester, blends, and more.

- No pre-treatment needed: unlike DTG printing.

- Bright and durable prints: colors stay vibrant after washing.

- Cost-effective for small orders: ideal for startups or custom shops.

- Easy to store transfers: print in bulk, press later.

⚖️ DTF Printing vs. Other Methods

| Method | Best For | Pre-treatment | Fabric Types | Durability |

|---|---|---|---|---|

| DTF | Versatile printing | ❌ No | Most fabrics | ✅ Excellent |

| DTG | Cotton printing | ✅ Yes | Cotton only | ✅ Excellent |

| Sublimation | Polyester items | ❌ No | Polyester only | ✅ Excellent |

| Heat Transfer Vinyl | Text or logos | ❌ No | All fabrics | ⏳ Moderate |

👉 DTF is more flexible than DTG or sublimation, and easier to use than vinyl.

🧰 What Equipment Do You Need?

To start DTF printing, you’ll need:

- A DTF printer (such as A3 or A4 size)

- DTF ink (CMYK + white)

- PET film (specially coated)

- Hot melt adhesive powder

- A curing oven or heat press

- A heat press machine for the final transfer

Tip: For smooth performance, choose printers like the Winnerjet A3 DTF Printer for better film feeding and reliable color output.

👥 Who Is DTF Printing For?

DTF is ideal for:

- Small clothing brands

- Custom T-shirt businesses

- Print-on-demand shops

- DIY creators and hobbyists

- Large printing factories looking to expand services

Whether you’re just starting or adding to your production line, DTF is a flexible and affordable choice.

💡 Tips for Better DTF Prints

- Keep your printer clean to avoid clogs

- Use high-quality films and inks for better color

- Store films flat in a dry place

- Pre-press garments to remove moisture

- Adjust pressure and temperature based on fabric type

Winnerjet DTF ink offers strong color saturation and low clogging, ideal for long-term printing performance.

🧾 Final Thoughts: Is DTF Printing Right for You?

DTF printing is easy to use, cost-effective, and highly flexible. Whether you’re a small business or just getting started, it lets you produce high-quality, full-color designs on many types of fabric with minimal hassle.

🎁 ✅ Request Free DTF Samples from Winnerjet

Not sure how DTF prints will look or feel?

🎉 Request a free sample pack from Winnerjet and test our premium DTF inks, films, and powders on your materials.

👉 Click here to request your sample.

❓ Frequently Asked Questions (FAQs)

Can I use a regular inkjet printer for DTF?

No. DTF printing needs a printer modified for DTF inks and white ink channels.

Is DTF printing better than sublimation?

DTF is more versatile since it works on cotton and blends, not just polyester.

How long do DTF prints last?

If done right, DTF prints can last through 40–50 washes or more.

Can I reuse the DTF film?

No, DTF film is single-use only.

Does DTF work on dark garments?

Yes! The white ink base makes DTF ideal for dark or colored fabrics.