When entering the custom apparel industry, the most critical decision you will make is selecting your consumables. So, what kind of ink do DTG printers use? Direct-to-Garment (DTG) printers utilize specially formulated Water-based Pigment Ink. Unlike standard office inkjet ink or traditional screen printing inks, DTG ink is engineered to bond with cotton fibers at a molecular level, ensuring a soft hand-feel and vibrant colors.

The Core Technology: Why Water-Based Pigment Ink?

DTG ink is not just a colored liquid; it is a sophisticated, nano-scale suspension fluid. To achieve Professional Results on fabric, a high-quality ink must maintain a precise balance between three core chemical components. As an experienced industry supplier, we understand how these factors impact your print quality and equipment lifespan:

Nano-scale Pigment: The Heart of Color Saturation

Pigments are the solid particles that provide color. Premium DTG Ink utilizes advanced nano-grinding technology to keep particle diameters under 0.2 micrometers. This ultra-fine particle size is the key to preventing Printhead clogging. If particles are too large or unevenly distributed, they will quickly wear down or permanently block the precision nozzles, leading to expensive repair costs.

High-Performance Binders: The Chemical Barrier for Durability

The binder acts as the “chemical glue” of the ink. Its job is to lock the pigment onto the cotton fibers during the heat-curing process. The quality of these Binders directly determines the Washfastness of the print. Low-end inks often suffer from an imbalanced binder ratio, causing the final product to fade, crack, or peel after just a few washes.

Professional-Grade Humectants: Guardians of Printhead Health

Humectants regulate the evaporation rate of the ink, ensuring it remains fluid at the nozzle rather than drying instantly during idle time. A superior moisturizing formula significantly reduces the frequency of automatic head cleanings, saving ink while dramatically extending the life of your printhead.

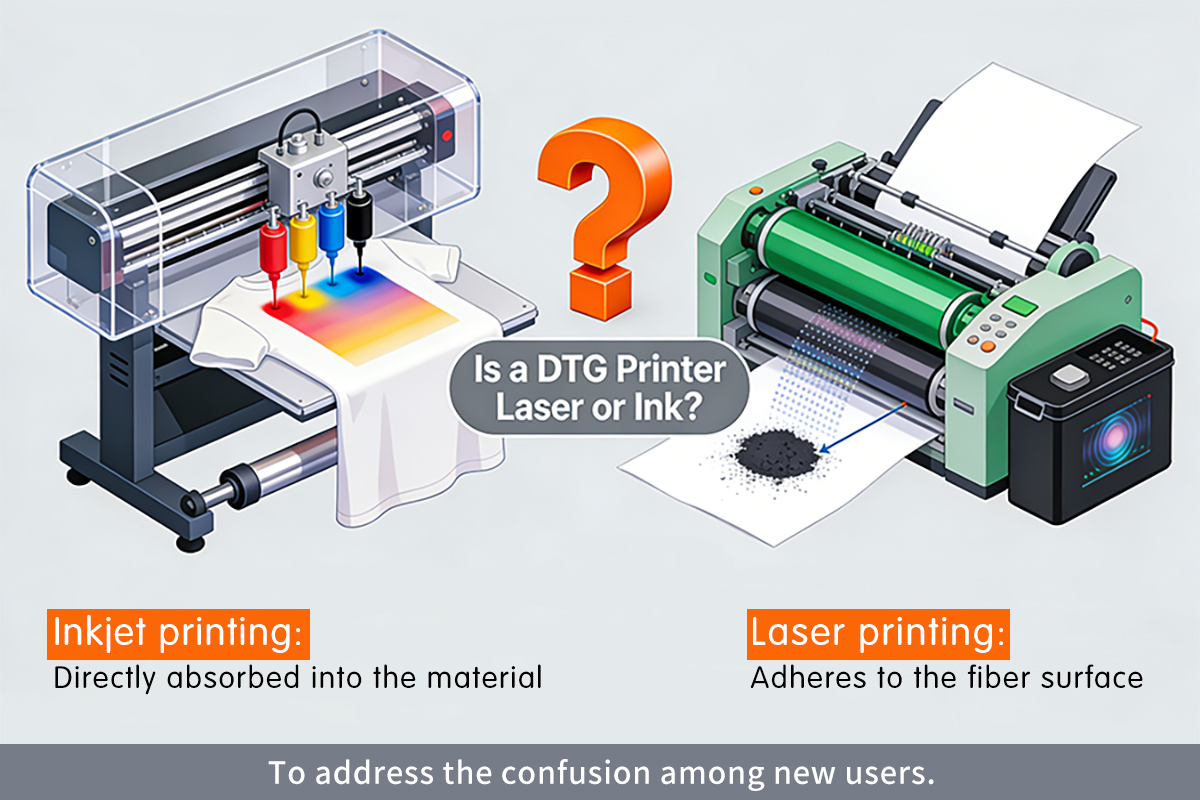

Industry Insight: Is DTG printer laser or ink?This is a common question for many entry-level customers.

To be clear: DTG is strictly Inkjet technology.

Laser technology uses dry toner melted at high temperatures, which only sits on the surface of the fabric, resulting in a stiff, non-breathable feel.

DTG (Inkjet) relies on liquid ink to penetrate the fibers. This physical characteristic is exactly why DTG offers superior color reproduction, a soft touch, and excellent breathability.

The Critical Role of White Ink in DTG

If you are printing on black or dark fabrics, White Ink is your most valuable asset. It serves as the foundation for your CMYK colors, directly determining the visual impact and success of the final garment.

Superior Opacity: The Foundation of Professional Results

Professional-grade white ink must have high opacity. Its mission is to completely mask the color of the dark fabric fibers, providing a clean, flat “white canvas” for the colored inks. If the Opacity is insufficient, the colored image on top will appear dull or muddy, failing to reproduce the true colors of your design.

Optimized Flowability: A Professional Solution for Sedimentation

White ink formulas contain high concentrations of Titanium Dioxide, a very heavy mineral that settles easily when static. This is the leading cause of Printhead clogging. High-quality DTG Ink uses advanced suspension technology to increase whiteness while significantly optimizing Flowability. This stability prevents pigments from clustering in the ink lines, reducing the need for frequent, wasteful cleanings.

Wet Strength and Compatibility: Chemical Synergy with Pretreatment

White ink must do more than just look white; it must react precisely with the Pretreatment liquid. Upon contact, the white ink must flash-dry and solidify instantly to prevent the ink from sinking too deep into the fibers or bleeding into the CMYK layer. This “flash-setting” characteristic is the technical core of ensuring sharp, crisp edges without blurring.

Technical Deep Dive: What is DTG ink made of?

To judge the quality of an ink, you must understand its chemical composition. As a professional consumable supplier, we break down DTG Ink into four critical dimensions that determine your printing performance.

Deionized Water: The Ultra-Pure Solvent Carrier

The main component of DTG Ink is water, but not just any water. Professional inks use multi-filtered deionized water. Removing minerals and impurities prevents scale buildup or unwanted chemical reactions within the heated printhead, ensuring absolute stability over long-term operation.

High-Load Pigment Dispersions: The Source of Color Intensity

Compared to budget inks, premium DTG Ink contains a much higher pigment load. This means you can use less ink to achieve more vibrant, deeper colors. These pigment particles are encapsulated in special surfactants to prevent Flocculation (clustering) in the bottle or ink system, ensuring color consistency in every drop.

Functional Additives: Balancing Physical Properties

Beyond pigment and water, various additives are used to tune the ink:

Surfactants: Control the surface tension and spread rate of ink droplets on fabric to prevent “bleeding.”

pH Buffers: Maintain the ink within a specific pH range to prevent corrosion of the printer’s internal metal parts and rubber seals.

Biocides: Prevent the growth of bacteria or mold in the water-based environment, extending the shelf life of the ink.

Cross-linking Resins: Achieving True Professional Results

This is what separates DTG Ink from standard inkjet ink. This special resin system undergoes a cross-linking reaction when heated (during the heat press process), forming a transparent, tough protective film. This film locks in the color and gives the print excellent stretchability, ensuring the design doesn’t crack when the garment is pulled.

Risk Warning: What happens if you use expired ink in a DTG printer?

In the DTG production process, many users ignore expiration dates to save costs. As professional suppliers, we must answer frankly: What happens if you use expired ink? Using expired or degraded ink ruins print quality and can cause irreversible damage to your hardware.

Physical Sedimentation: The “Printhead Killer”

DTG ink is a precision suspension, especially White Ink. Once past its shelf life, the suspension agents fail, and pigment particles cluster into hard sediment. These particles permanently block the microscopic filters and nozzles inside the printhead. Often, even aggressive cleanings cannot recover the head, resulting in a replacement cost of thousands of dollars.

Chemical Breakdown: Total Failure of Washability and Color

The Binders in expired DTG Ink degrade over time. This means that even if the print looks vibrant initially, the pigment will fail to bond with the fibers during curing. The result is severe cracking or massive fading after the first wash, a quality disaster that wastes garments and destroys customer trust.

pH Imbalance: Invisible Corrosion of Internal Components

Over time, the chemical balance of the ink shifts, potentially becoming too acidic or alkaline. This instability slowly corrodes internal rubber seals, dampers, and pump assemblies. This damage is often hidden until a leak or pressure system failure occurs, at which point the maintenance costs far exceed what was saved on ink.

How to Choose the Right Ink for Your Business?

To earn the repeat business of your customers, you need more than just cheap consumables; you need three core pillars that support a long-term business. At Winnerjet, having worked with hundreds of print shops globally, we advise owners to consider these commercial dimensions:

Color Gamut: Determining Your Profit Margin

Excellent ink must have a wide Color Gamut. It needs to reproduce high-saturation colors as well as delicate skin tones and gradients. Color performance determines the “class” of your product. If your colors are dull or grey, you will struggle to command premium prices in the high-end custom market.

Clog-resistance: The Hidden Profit Killer

For business owners, downtime means lost profit. Clog-resistance directly determines your production efficiency. High-quality ink remains fluid at the nozzle even after short idle periods. We have optimized our moisturizing formulas to reduce non-essential cleanings by over 30%, protecting your expensive printhead and saving on wasted ink costs.

Stability: The Foundation of B2B Business

Repeat orders are the lifeblood of a company. Stability means that whether you buy ink today or three months from now, every batch must perform identically. Batch-to-batch color deviation is a major cause of customer churn. At Winnerjet, we enforce strict calibration standards to ensure your customers receive the exact same quality every time.

At Winnerjet, we provide more than just ink; we provide a Total Production Stability Solution. Whether you are using flexible modified equipment or high-volume industrial lines, our solutions have been stress-tested in mass-production environments. We don’t just pursue the lowest price for a single transaction; we provide the ultimate stability to help you build an industry-leading reputation.

Want to elevate your print quality?

Don’t let low-quality consumables limit your growth. Explore the Winnerjet range of professional DTG Ink, pretreatment liquids, and cleaning solutions today.

[Browse Our Product Line] | [Consult a Technical Expert]

FAQ

Is DTG printer laser or ink?

It is an inkjet technology that uses liquid ink to penetrate fibers, offering much better breathability than laser toner.

What is DTG ink made of?

It is primarily composed of pigment, water, resin (binders), and humectants. The precise ratio determines if it will clog the printhead.

What happens if you use expired ink?

It leads to severe printhead clogging and print failure, resulting in unnecessary and expensive repair costs.