In the current market, the price of XP600 DTF printers generally ranges from USD 1,500 to over USD 4,000. Many buyers find this confusing when comparing options for the first time: if they all use the same XP600 printhead, why is there such a large price gap?

In reality, this situation is not unusual. XP600 refers only to the printhead model and does not represent the overall configuration or performance of the entire machine. Different manufacturers vary significantly in machine structure, white ink circulation systems, whether curing ovens or powder shaker units are included, and the level of after-sales support provided. These differences are ultimately reflected in the final price.

For this reason, price alone is not a reliable indicator of an XP600 DTF printer’s real value. In the sections below, we break down what you can typically expect at different budget levels, the configurations commonly included, and the use cases they are best suited for—helping you determine which price range aligns best with your actual needs.

XP600 DTF Printer Price Tiers in Practice

XP600 is one of the most widely used printheads in the DTF market. However, there has long been a significant perception gap around XP600 DTF printer pricing. Even machines using the same XP600 printhead can differ in price by more than double.

From a practical configuration and usage perspective, XP600 DTF printers generally fall into three categories: entry-level, mid-range, and high-end. Having the same printhead does not mean equal performance. Overall machine structure, system design, and integrated solutions are the real factors that determine both price and long-term user experience.

Entry-Level XP600 DTF Printers (Approx. USD 1,500–2,000)

At this price point, the positioning of XP600 DTF printers is very clear: low-cost entry into DTF printing. Typical configurations include a single XP600 printhead, A4 or A3 printing width, and a basic white ink circulation or stirring system. Daily maintenance relies heavily on manual operation.

Products in this range are commonly found as entry-level models on e-commerce platforms, OEM solutions, or even systems assembled by small workshops. Most professional suppliers, including companies like Winnerjet, also offer basic models in this price range, primarily targeting beginners.

The main advantage of this category is its low upfront investment and quick learning curve. For users who are new to DTF printing or entrepreneurs who want to test market demand before committing significant capital, these machines allow basic production at relatively low risk. They help users become familiar with workflows, consumable usage, and customer feedback.

However, it is important to understand the limitations. Entry-level XP600 DTF printers typically have restricted stability and limited capability for long, continuous operation. White ink requires frequent maintenance, and extended running hours increase the risk of clogging or inconsistent output. After-sales support at this level is usually limited to basic technical guidance. Once order volume grows, these machines can quickly become a production bottleneck.

As a result, this category is best suited for beginners, small customization shops, or startup studios, where the focus is on low entry barriers rather than sustained commercial production.

Tip: If you are an entrepreneur without stable orders yet, this level is generally sufficient for your current needs.

Mid-Range XP600 DTF Printers (Approx. USD 2,000–3,000)

The mid-range segment is the most common and most balanced choice among XP600 DTF printers. Machines in this range usually offer noticeably improved stability, more mature mainboards and control systems, and better-designed white ink circulation. Some models can also be paired with curing ovens or semi-integrated solutions.

This price range typically includes established DTF brand models, where manufacturers begin to prioritize long-term usability rather than simple specification stacking. For small businesses with steady orders, these machines can reliably support daily production without frequent interruptions.

The main challenge in this segment lies in brand variability. On the surface, many machines appear similar, but differences in build quality, system stability, after-sales response, and consumable compatibility can be significant. At this price point, brand reputation and support quality are often more important than price alone.

From an overall cost-performance perspective, this range is often considered the best value segment within XP600-based solutions.

Tip: If you already have stable orders and want to reduce the time spent on daily maintenance, this tier is closer to a truly sustainable business setup.

High-End XP600 DTF Printers (Approx. USD 3,000–4,000+)

Once XP600 DTF printers reach this price level, they are clearly positioned for commercial production environments. Typical configurations include dual XP600 printheads, fully integrated curing ovens and powder shaking systems, as well as automatic cleaning and maintenance functions. The goal is to increase throughput, reduce manual intervention, and minimize downtime risk.

These machines are usually offered by brands that provide complete DTF solutions, emphasizing stability, continuous production capability, and structured after-sales support. For businesses with consistent order volume and long daily operating hours, this category can significantly improve efficiency and production predictability.

The trade-off is a higher initial investment. If order volume is unstable, the return on investment cycle may be longer. At this budget level, some users also begin to compare alternatives using higher-spec printheads such as the i3200.

As a result, this tier is best suited for businesses with clearly defined production scale, where minimizing production risk is a core objective.

Tip: For commercial operations, high-end configurations only show their real value when the cost of one day of downtime clearly exceeds the price difference between machine tiers.

Key Factors Behind XP600 DTF Printer Price Differences

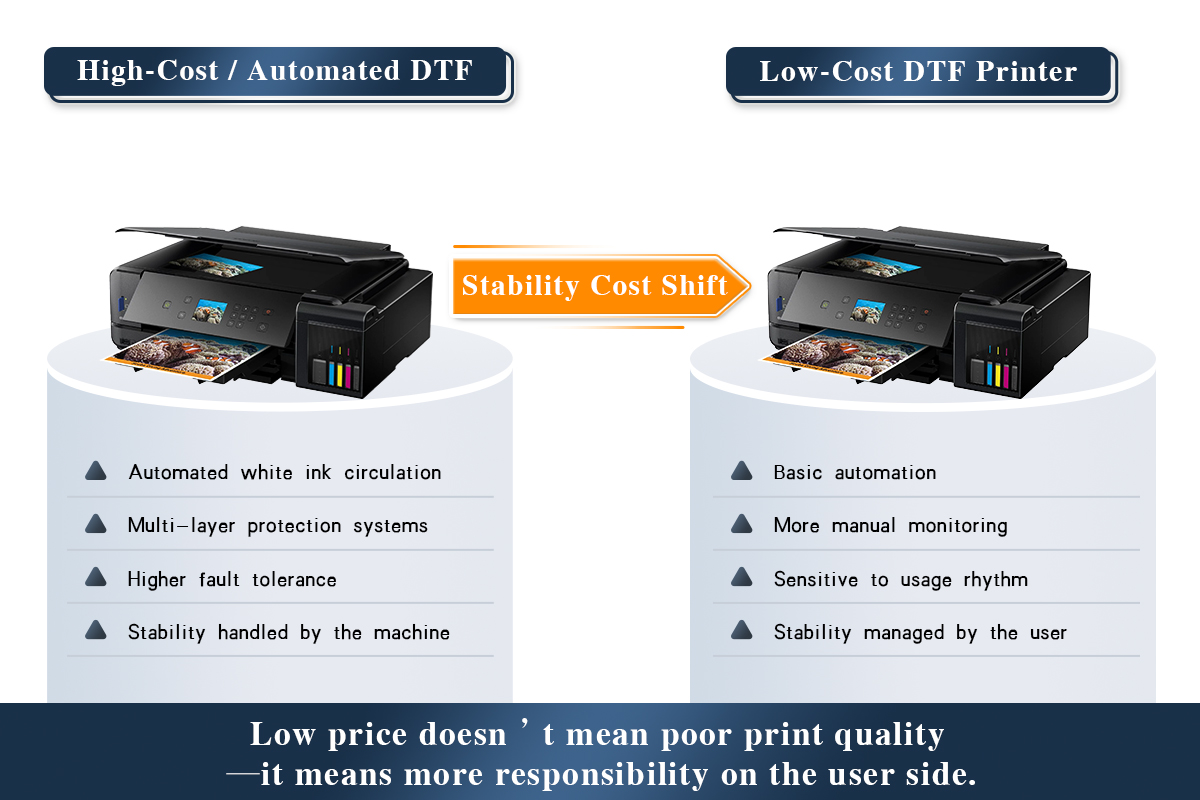

Many buyers ask the same question: if the XP600 printhead is the same, why do prices vary so much? The answer lies in the fact that the printhead is only one component of the DTF system. Differences in overall machine design, system stability, and long-term operating costs all directly affect pricing.

1. Number of Printheads: Single vs. Dual

Single XP600 configurations are common in entry-level and mid-range machines, offering simpler structures and controlled costs. Dual XP600 setups deliver higher printing speeds but also require stronger data processing, more precise printhead synchronization, and higher-performance mainboards. These hidden system upgrades largely explain the price gap between single- and dual-head models.

2. Integrated Oven and Powder Shaker Systems

Machines sold as standalone printers rely more heavily on manual post-processing. Semi- or fully integrated solutions that include curing ovens and powder shakers significantly improve efficiency and consistency but also increase mechanical and electrical complexity, which raises costs.

3. White Ink System Design

White ink handling is often more critical than color ink in DTF printing. Entry-level machines use basic circulation or stirring systems suitable for low-frequency use. Higher-end machines feature more refined circulation paths, filtration, and sediment control, reducing clogging risk and improving long-term stability. In practice, white ink system quality has a greater impact on maintenance frequency than the printhead model itself.

4. Electronic Control Systems and Overall Stability

Even with the same printhead, manufacturers vary widely in their investment in mainboards, electronic control systems, and software optimization. Mature systems ensure stable data transmission, consistent output, and longer continuous operation—factors that are not always visible in specification sheets but are critical in daily use.

5. After-Sales Support and Consumable Compatibility

One often overlooked factor is the support ecosystem. Some suppliers sell hardware only, while others also provide inks, films, powders, and ongoing technical guidance. Suppliers like Winnerjet, which offer XP600 DTF printer solutions alongside matched consumables and structured after-sales support, may not always appear as the lowest-priced option. However, such integrated support can significantly reduce uncertainty and operational risk over time.

Long-Term Costs Often Overlooked When Buying an XP600 DTF Printer

The purchase price is only the first step. What truly differentiates user experience and total cost of ownership are the long-term costs that are easy to overlook during the buying stage.

- Consumable Costs

Different machines vary significantly in their compatibility with white ink, color ink, films, and powders. Poor white ink system design often leads to higher ink consumption and more frequent cleaning, increasing per-unit production costs over time. From long-term cooperation with DTF printing businesses in different regions, it is clear that machine–ink compatibility directly affects consumable usage and maintenance frequency. As an ink solution provider, Winnerjet focuses on these operational details rather than one-time equipment pricing, helping users maintain more predictable long-term performance. - Hidden Risk of Printhead Replacement

XP600 printheads are not inexpensive, and their lifespan is closely tied to white ink system design and maintenance conditions. Low-cost machines may appear acceptable in the short term, but as usage increases, the risk of clogging or performance degradation rises, often leading to earlier-than-expected printhead replacement. - Time Cost of Daily Maintenance

Lower-end machines typically require more manual maintenance, including frequent cleaning, air purging, and status adjustments. For businesses with steady orders, the time spent “managing the machine” becomes a hidden operational cost. - Availability and Quality of Technical Support

Some suppliers provide strong pre-sales communication but fragmented or paid after-sales support. In contrast, suppliers with long-term partnerships and complete consumable and technical systems are more capable of delivering consistent, practical support. Winnerjet’s high repeat purchase rate is built on ongoing quality control and long-term cooperation rather than one-time equipment sales. - Logistics and Import Costs for International Buyers

For international customers, logistics and customs duties are not one-time considerations. The ability to reliably deliver machines, spare parts, and consumables depends on the supplier’s global fulfillment experience. Suppliers serving multiple regions typically plan logistics and compliance early, reducing unexpected delivery risks and costs over time.

Which XP600 DTF Printer Budget Is Right for You?

After understanding configuration differences and long-term costs, choosing the right budget becomes less about “which machine is cheaper” and more about matching your business stage and stability requirements.

- Limited budget: Entry-level XP600 machines offer a low-risk starting point but require higher maintenance involvement.

- Focus on stability: Mid-range XP600 machines strike a balance between cost and reliability, often delivering the best long-term value.

- Production-dependent: High-end XP600 configurations reduce downtime risk and reliance on operator experience, making them suitable for commercial environments with consistent demand.

Pre-Purchase Self-Assessment Checklist

Before comparing prices and specifications, clearly defining your usage scenario is often more important than parameters alone.

| Self-Check Question | What You Should Consider | Impact on Your Decision |

|---|---|---|

| How many hours will I run the printer each day? | Occasional use or several hours of continuous daily operation | Longer runtime requires higher stability and better system design |

| How much maintenance can I realistically handle? | Time available for white ink circulation, cleaning, and daily checks | Limited maintenance time favors more stable and automated setups |

| What does one day of downtime cost me? | Delayed delivery, lost revenue, or reduced customer trust | Higher downtime cost means reliability becomes a top priority |

| Is consumable supply stable and reliable? | Long-term availability of ink, powder, and related materials | Unstable consumables directly affect production continuity |

| Is technical support clear and accessible? | Response speed, support channels, and whether service is included | Support quality often matters more than raw hardware specs |

| Is my order volume likely to grow? | Plans to scale production or increase daily output | Growth expectations should be reflected in current equipment choices |

Tip: If you rate “high requirement” on three or more items, focusing only on the lowest price is usually not recommended.

Final Consideration

Choosing the right XP600 DTF printer does not mean selecting the cheapest option—it means finding the right balance between cost, stability, and long-term value based on your business stage. Entry-level machines reduce trial-and-error risk, while higher configurations better serve stability-driven production environments—provided their capabilities are truly utilized.

Understanding the system design, white ink management, and maintenance costs behind price differences helps avoid decisions based solely on quotes. In many cases, a well-matched and stable machine delivers more predictable efficiency and cost control over time.

Ultimately, mature DTF procurement is not about a one-time equipment purchase, but about choosing a solution that can grow with your workflow. The real value of a DTF printer lies in how smoothly it integrates into your production process—when equipment, consumables, and support are aligned with actual needs, efficiency and cost optimization tend to follow naturally.