As demand for personalized apparel and small-batch printing continues to grow, DTF (Direct to Film) printers have gradually become a key focus for many studios and startups. Among the many brands on the market, XTool DTF printers consistently attract strong search interest. One of the most frequently asked questions is: Is the price of an XTool DTF printer really high—and is it worth buying?

Before making a purchasing decision, simply knowing a single “price number” is far from enough. From a buying perspective, this article aims to help you more rationally understand XTool’s DTF pricing, its cost structure, and its position in the market.

1. XTool DTF Printer Price Range

Based on mainstream configurations currently available, XTool DTF printers are generally positioned in the mid-to-high price range. This pricing strategy reflects that XTool primarily targets users who place higher value on operational stability and complete workflow solutions.

| Type | Typical Use Case | Price Range (USD) | Notes |

|---|---|---|---|

| Entry-level / Basic setup | Small-scale printing, personalization, beginners | $2,000 – $5,000 | Usually desktop models, A4 / A3 formats |

| Standard commercial setup | Small studios or regular order production | $10,000 – $25,000 | Improved performance and stability for continuous work |

| Fully automated system | Industrial, high-volume production | $30,000+ | Includes powder shaking, curing, and automated modules |

For this reason, XTool DTF printers may initially feel “expensive,” but when viewed as a complete production solution rather than a single machine, the pricing logic becomes easier to understand.

2. Where Is the XTool DTF Price Higher?

Price differences in DTF printers are rarely accidental—they are driven by multiple underlying factors. XTool’s relatively higher pricing in the industry mainly comes down to the following aspects:

1) Higher Level of System Integration

Compared with solutions that require users to assemble equipment themselves, XTool emphasizes a “ready-to-use out-of-the-box” workflow. Its systems typically include not only the printer, but also automatic powder shaking and curing units, forming a relatively complete production line.

Naturally, such integrated solutions cost more than basic printer-only setups.

To better illustrate this difference, here is a comparison of typical price ranges across brands:

| Brand / Solution Type | Typical Price Range (USD) | Complete Workflow Included |

|---|---|---|

| Entry-level desktop brands (e.g., Easythreed) | ~$1,000 – $2,500 | ❌ Printing only; powder & curing required separately |

| Mimaki / Roland converted DTF systems | ~$2,500 – $5,500 | ⚠ Converted setups; workflow equipment required |

| Winnerjet basic DTF solutions | ~$3,000 – $6,000 | ⚠ Printer-focused; some modules sold separately |

| Epson converted DTF kits | ~$3,000 – $8,000 | ⚠ Epson-based conversions; external equipment needed |

| XTool integrated DTF series | ~$5,000 – $10,000+ | ✅ Printer + powder + basic curing included |

| Industrial brands (Kornit / Afinia Pro) | ~$20,000 – $50,000+ | ✅ Fully automated, enterprise-level systems |

In comparison, entry-level and converted DTF solutions are cheaper but usually fragmented; value-focused brands like Winnerjet offer better affordability but with limited automation; industrial brands such as Kornit or Afinia Pro are priced far above XTool and target entirely different high-volume markets.

This explains why XTool appears more expensive—it delivers printing, powdering, and curing as a unified system, rather than selling individual components separately.

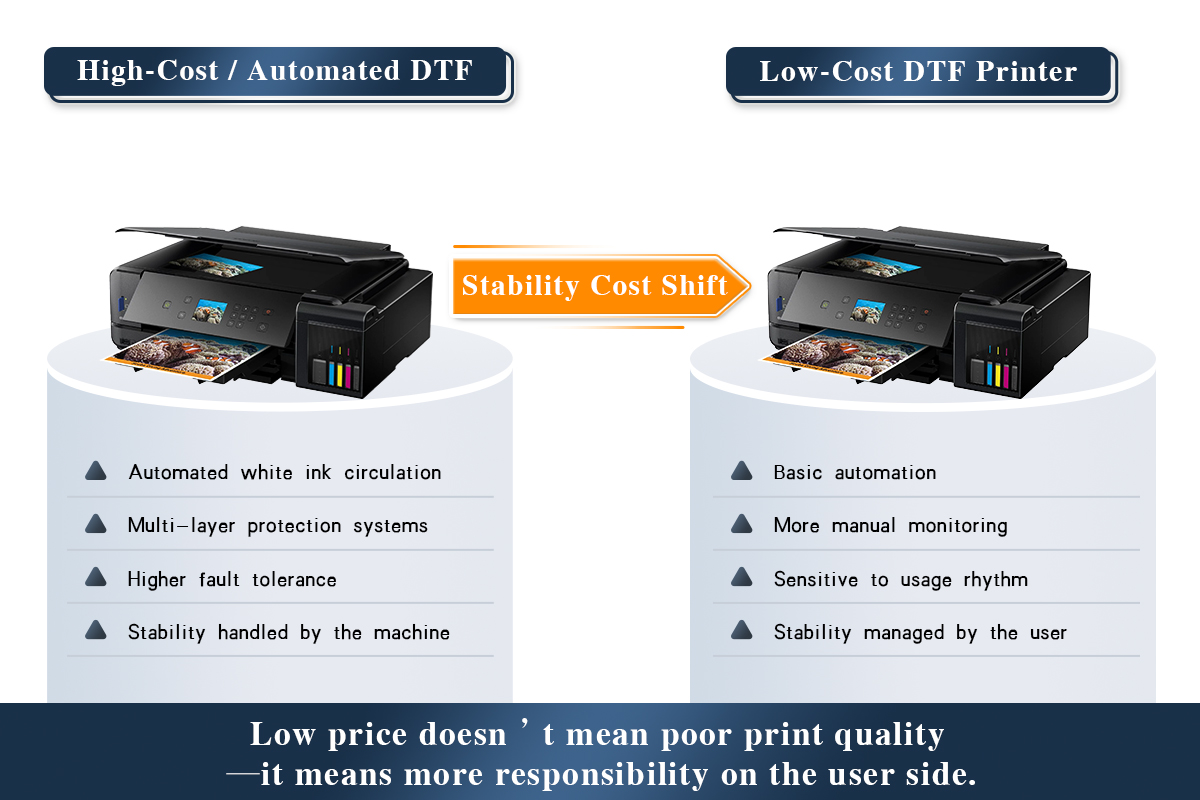

2) Configuration Focused on Stability and Ease of Use

XTool’s system design clearly prioritizes automation, ease of operation, and overall stability. As a result, users can avoid spending large amounts of time on parameter tuning or equipment integration and enter production more quickly.

For example, Epson-based converted DTF kits often require users to install powder shakers, match curing ovens, and manually coordinate each step—creating a higher learning curve for beginners. XTool reduces this barrier through integrated workflow design and preset configurations.

Therefore, XTool’s pricing reflects not only hardware costs, but also the value of saved time and reduced operational complexity, which many basic solutions cannot provide.

3) Designed for Long-Term Use

XTool pricing also accounts for long-term operating efficiency, system stability, and usability. For users planning to run DTF printing as an ongoing business, a smooth, compatible, and low-maintenance system often delivers more value than a cheaper setup that “only prints.”

From this perspective, XTool’s pricing can be viewed as an upfront investment in long-term reliability and efficiency.

3. XTool’s Market Position and Value Range

After understanding why DTF solutions vary in price, it becomes easier to see why XTool is often compared with more cost-focused brands—most commonly Winnerjet.

From a pure pricing perspective, the distinction is clear:

- Winnerjet typically enters the market with lower entry prices, making it suitable for users with limited budgets who want to control initial investment and start DTF printing quickly.

- XTool is priced higher overall and focuses on providing a more complete, smoother, and lower-adjustment-cost DTF solution.

As a result, buyers who prioritize upfront machine cost often find Winnerjet easier to fit into their budget. On the other hand, users willing to invest more initially to reduce later equipment integration, tuning, and maintenance effort may find XTool’s pricing more acceptable.

From this angle, the difference between XTool and Winnerjet is not about “better or worse,” but about serving users at different stages and with different budget strategies.

4. When Buying a DTF Printer, Price Is Not the Only Criterion

Comparing XTool’s pricing with other brands shows that the difference is rarely just about “cheap vs. expensive,” but rather reflects fundamentally different product philosophies and usage scenarios.

In real-world purchasing decisions, many users focus too heavily on the machine’s sticker price while overlooking long-term costs that significantly affect efficiency and profitability.

Commonly underestimated costs include:

❗ Long-term consumption of ink and hot-melt powder—differences in material efficiency can lead to substantial cost gaps over time

❗ Time spent on daily maintenance and cleaning—more manual systems demand greater ongoing effort

❗ Equipment stability and its impact on order delivery—frequent downtime increases risk and rework

❗ Additional purchases of powder shakers, curing units, or other accessories that raise total investment later

As a result, some lower-priced solutions end up costing more over time due to added equipment and maintenance. In contrast, higher-priced but more complete systems often offer stronger long-term cost control and production stability.

5. From a Buyer’s Perspective: Which Price Tier Fits Which Users?

After understanding XTool’s pricing logic and long-term cost considerations, comparing it with value-oriented brands like Winnerjet makes trade-offs clearer.

Users More Suitable for XTool DTF

XTool is generally a better fit if you:

- Want to minimize time spent on equipment matching and workflow integration

- Require stable, continuous production and reliable delivery

- Prefer not to repeatedly invest effort in tuning, maintenance, and configuration

- Plan to run DTF as a long-term business rather than a short-term trial

For these users, XTool’s price represents payment for a mature user experience and stable output, with higher upfront cost but lower long-term uncertainty.

Users More Suitable for Winnerjet and Other Value-Oriented Options

Winnerjet is positioned more toward controlling initial investment and is suitable if you:

- Have a limited budget and want to enter the DTF market at lower cost

- Are still experimenting with or learning DTF printing

- Are comfortable spending more time on workflow optimization and equipment selection

- Operate at smaller scale or with flexible order schedules

Winnerjet’s strengths lie in its lower entry threshold and flexible model options. However, automation and workflow smoothness often depend on user-side integration.

At the same time, Winnerjet, as a professional eco-friendly ink manufacturer, offers stable consumables supply, which can help reduce long-term operating costs.

Buying Recommendation from a Price Perspective

From a pricing standpoint, Winnerjet emphasizes accessibility, while XTool emphasizes system completeness. The difference is not raw performance, but a trade-off between upfront investment and long-term ease of use.

Ultimately, the right choice depends on whether you prioritize minimizing initial purchase cost or reducing long-term operational complexity and uncertainty.

Conclusion: How to Rationally Evaluate XTool DTF Pricing

From a market positioning perspective, XTool DTF printers are not entry-level budget products. They are designed for users seeking complete workflows and higher operational stability. Their pricing reflects not just the printer itself, but also system integration, ease of use, and long-term reliability.

Before making a decision, instead of simply asking “Is XTool expensive?”, consider these questions:

- What is my acceptable budget range?

- Do I value long-term stability and convenience more than low entry cost?

- Do I want to reduce uncertainty from equipment matching, tuning, and maintenance?

If your priority is fast production startup, smooth workflows, and controlled long-term costs, XTool’s pricing is often reasonable. If your main goal is to minimize upfront investment, value-oriented options such as Winnerjet may be more suitable.

Conclusion: Whether XTool is “expensive” depends on your business stage and purchasing goals—not on price numbers alone.